The daily life and quality of life of future users for half a century depend on it, but not only. Every technology, every material implemented today supports its development for the future.

We are well aware of the leverage and responsibility that we, as architects, carry with us when we initiate each new project.

In this case, it is a question of building six-apartment rental building on a plot located in the city of Lausanne. For questions of financial accessibility of rents, the investment must remain reasonable, which does not mean that all construction costs must be reduced to the floor.

Indeed, for each franc invested the return for the owner must be measured in an informed manner. These returns are very different:

- The mortgage financing facility and preferential rates in the context of the construction of an energy-efficient property.

- The Minergie-P certification of the building permits a bonus of building area and optimises the use of the plot.

- Low maintenance costs thanks to the quality of design and the use of quality materials.

- As part of a regular increase in the charges to tenants, a minimisation of the charge/rent ratio supports the development of lots.

- The reduction in the tenant vacancy rate thanks to the comfort and well-being of the different apartments

For technical questions and because of the lack of alternatives, the basement and the various underground parts are built in the traditional way in reinforced concrete. Concrete was also chosen for the construction of the exterior stairwell/lift. It would be possible to execute the latter in wood using a species, such as beech, that offers the necessary fire resistance. However, this stairwell/lift being exposed to bad weather, the construction costs to which it will be necessary to add the maintenance and the regular repairs made us opt for the masonry solution.

The residential buildings strictly speaking, which represent the largest built volume, will on the other hand be designed with a timber frame. This solution allows us to minimise the grey energy generated during construction. It also guarantees the project owner the smallest scope of work thanks to the prefabrication of the main facade and floor elements.

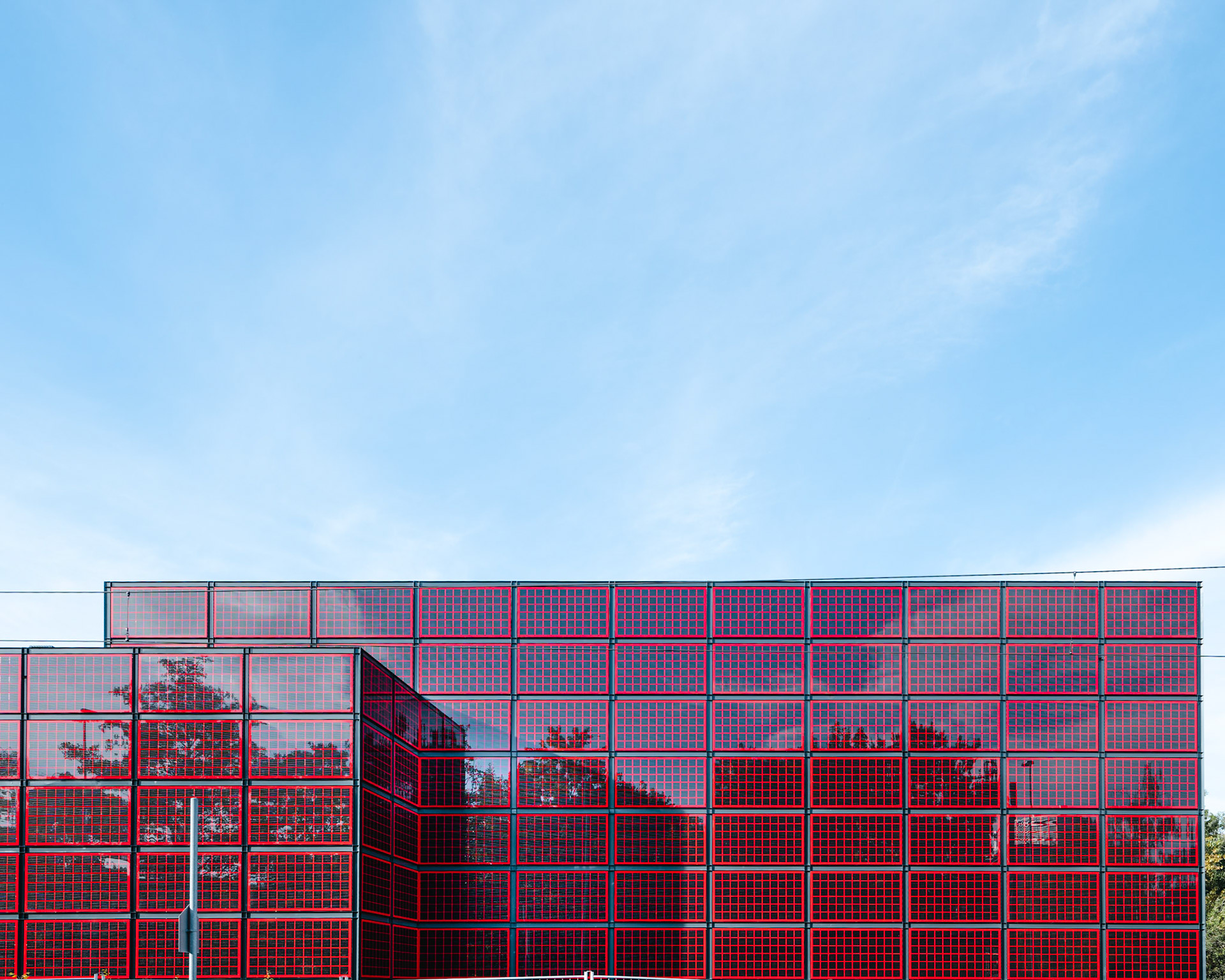

The exterior cladding of the building uses a ventilated facade in corrugated Eternit. This technical solution, in line with the organic insulation of the walls, guarantees the best thermal protection in winter as in summer. In addition, compared to compact synthetic insulation, ventilated facades have a three times longer lifespan.

We are currently studying the possibility of making part of the interior partitions using mud bricks. In addition to the aesthetics and ecological qualities of the material, the latter provides an interesting mass of inertia, able to store heat in winter. Like wood, raw earth plays a very positive role because of its ability to absorb excess moisture and release it in drier periods.

As you can see in the pictures, the flat roofs of both residential buildings are accessible to the inhabitants and are available to them as meeting and exchange spaces. The two roofs are surrounded by garden boxes incidentally playing the role of railings.

From an energy point of view, the building is designed according to the Minergie-P specifications. To meet the most demanding building standards in the country, in addition to the wooden frame which ideally lends itself to a homogeneous integration of the insulation, we opted for a geothermal heat pump associated with the solar power plant located on the roof.

Double flow ventilation allows the optimal renewal of the air during periods of extreme heat and cold. It goes without saying, and contrary to urban legend, that the opening of the windows is at the discretion of the inhabitants. The mechanism simply relieves them of daily winter ventilation and recovers 90% of the heat from the stale air during these cold spells.

Another advantage of the heat pump/controlled ventilation coupling during hot weather; the pump mechanism switches to reversible mode and cools the floors of the apartments while reinjecting the heat recovered into the sub-soil. The heat will then be stored until the following winter.

Without being exhaustive, the above text gives an overview of the possibilities offered today in terms of construction. This project is not a foresight exercise but simply an example of what can be achieved rationally by following the best practices available in 2022.

Currently in its finalisation phase, the project will be submitted for authorisations in early 2023. We sincerely hope to be able to share with you behind the scenes of the construction during the course of next year.