The building houses 80 student rooms, a performance hall with a capacity of 200 people and numerous conference rooms. Founded in the early 1970s with the aim of welcoming students from the Vaud countryside to the city, the Cazard Foundation continues its hospitality and cultural vocation today.

Designed and built just before the 1973 oil crisis, the architecture of this building gives pride of place to the creative freedom of the architect and the carefree energy consumption that prevailed then. The roofs, facades as well as the technical elements of heat production and ventilation reaching the end of their life cycle, our workshop was responsible for projecting the venerable building into the 21st century.

The works to be undertaken

- Asbestos removal and perimeter insulation of facades

- Insulation and sealing of terraces and roofs

- Replacement of all heating and ventilation systems

The objective is to implement the most energy-efficient technical means by using materials and processes offering the best sustainability factors.

Not insignificant data, the building is located in an environment of high built density and the financial framework of the project is set in an extremely rational way.

A first phase of technical evaluation of the existing structure was followed by an architectural design phase. Accompanied by heating-ventilation and facade engineers, we have now achieved a tangible project that meets the client’s specifications.

We will present to you in the rest of this article the main axes of transformation allowing this building, which was built 50 years ago, to reposition itself in a contemporary way and with the highest energy standards applicable today.

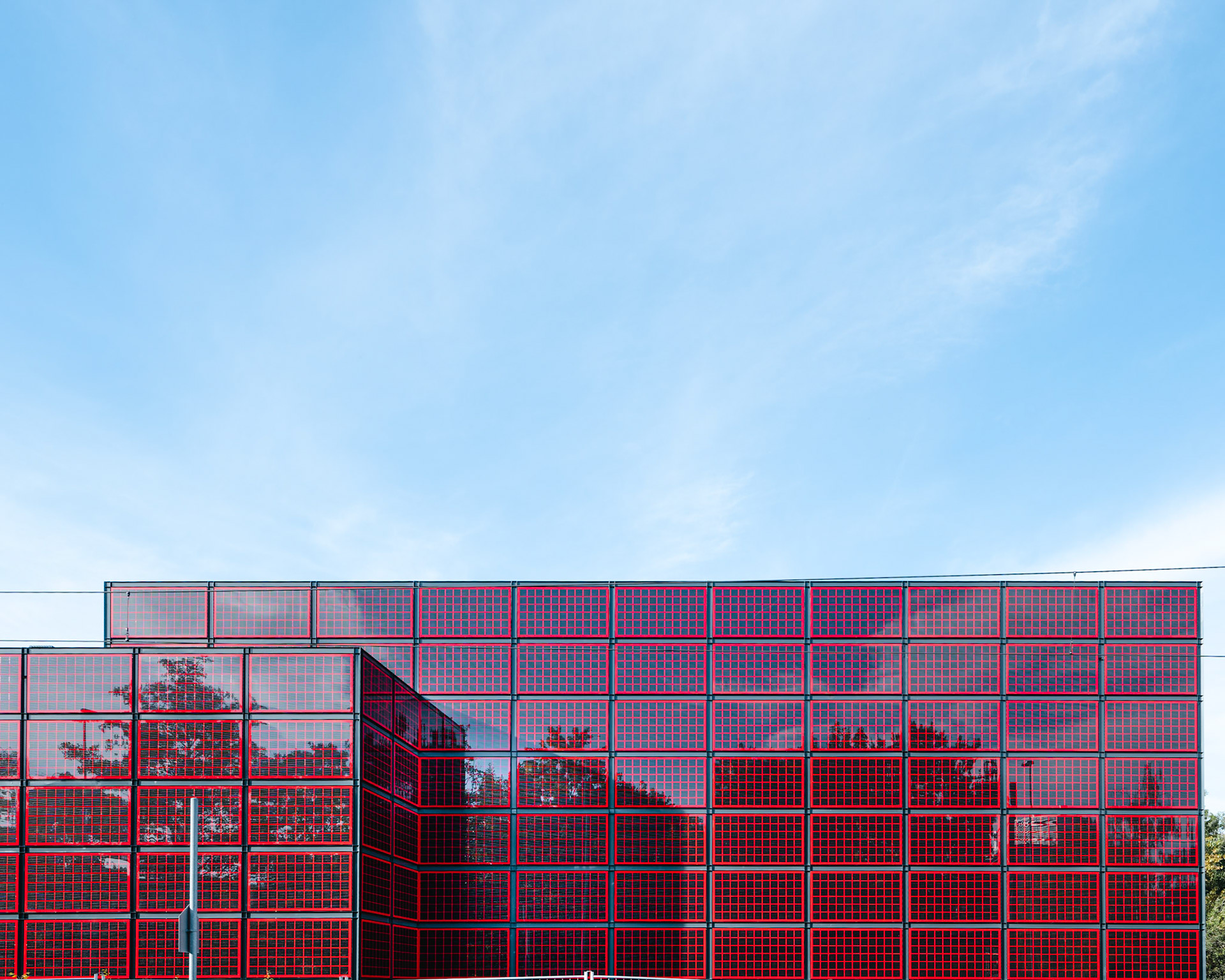

Facades

The current recessed facades are covered with Eternit asbestos sheets and have virtually no insulation. The configuration of the latter and the integration of the windows do not offer any possibility of perimeter insulation according to the existing openings.

Based on this first observation, we chose to remove the entire Eternit sheeting and cover the building with a new skin in the form of a curtain facade. The latter is “stretched” on the outside of the currently protruding angles of the silhouette. With both economic and sustainability concerns in mind, the structure is made up of wooden load-bearing elements and mostly organic insulation. In addition to the carbon sink effect, wood and organic wool offer a much greater thermal phase shift than synthetic and mineral materials. Comfort in the summer period is therefore significantly improved.

The exterior coating is still under discussion but is moving towards the new-generation Eternit for its characteristics and its implementation particularly adapted to our situation. The Eternit also has the advantage of being produced in a very ecological way less than 50 km from the site.

The last element concerning the external aspect of the project is the revegetation. The recent passage of the district into a pedestrian zone and the tree planting project that accompanied it convinced us to install plants on the facade. The implementation is still under study but the principle is to circulate vines along cables stretched vertically between the lines of window.

The roofs

The flat roofs of the inner courtyard and the roof are in poor condition. The covering materials are partially broken and the waterproofing begins to take in water during major storms. These roofs will therefore be completely uncovered, insulated and sealed. New paving will be installed in the courtyard and the finish of the upper flat roof remains to be determined according to the technical equipment it will receive.

The bi-pan roof, now covered with tiles, will be stripped. Insulation based on compressed wood fibres will be installed on the existing frame and finally covered with integrated photovoltaic panels. This solution will eliminate the need for tiles.

Heating and ventilation

The building is currently heated by an oil-fired boiler dating back to 1995, developing an output of 435 kW. Heat distribution is via high-temperature radiators without thermostatic valves and powered in series. This heating technique, which was very simple and widespread during the 1970s, made balancing the networks and the proper distribution of heat in the various rooms very complex.

On the ventilation side, the existing installations are numerous and of the double-flow type without heat recovery. These installations are at the end of their life and have extremely poor energy efficiency since they do not have a heat recovery system.

With this equipment and the virtual absence of insulation, the building consumes 520,000 kWh/year and is in energy class G.

As part of the renewal of the facilities, the choice of an air-to-water heat pump installed on the roof was made. The latter will be coupled with the 170m2 of the photovoltaic power plant installed on the roof. The entire heat distribution system will be replaced and will circulate between the current facade and the new skin of the building. New convectors equipped with thermostatic valves will also be installed in all the premises.

As regards the ventilation systems, these will be completely renewed and replaced by heat recovery systems.

Miracles are possible

Given all the technical interventions and the complete insulation of the building, it will gain five levels to reach energy class B!

It is therefore interesting to note that it is now possible to carry out extremely efficient transformations both from an energy point of view and in terms of the comfort of the inhabitants on infrastructures that were built according to specifications far from current considerations.

The other very interesting point financially is that beyond the significant energy savings promised, the work will be able to be carried out while maintaining a large part of the Foundation's activity, therefore maintaining its financial income.